They reserve work in progress for larger-scale projects like consulting or construction work. Another reason for work in process inventory is safety stock, buffer stock, or anticipation inventory. Some companies find it beneficial to hold on to goods at certain stages of production as insurance against shortages of supply or spikes in demand.

The accurate number of inventory by regularly counting the stock will give the manufacturer a fair idea of how much needs to be produced and also help in forecasting the production as per the demand. When you keep track of your work-in-process inventory, it can have a significant impact on your business and its balance sheet. Work-in-process stock keeps changing based on the products, the cost of producing finished goods, and how to accurately calculate WIP inventory for accounting and financial purposes. Work in process (WIP) inventory refers to partly finished goods that come in between raw materials and final products in the production process.

Why Is Accurate Work-in-process Accounting Important?

Understand what you want, what the other person wants, the potential alternatives, and any challenges or obstacles you might face. Three of these techniques are skills that focus on preparation, probing during the process, and proposing your solution. However, there are certain skills and techniques that negotiation experts often recommend. Negotiation skills are varied and complex, since the process is so dynamic and multifaceted. No two people or situations are exactly the same, so the skills and strategies you’ll need can vary.

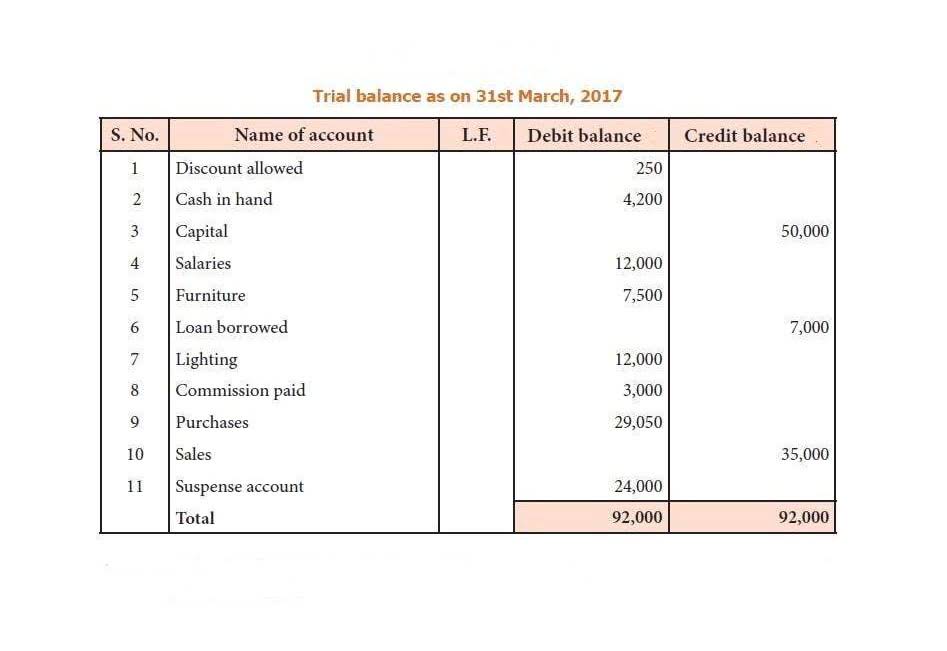

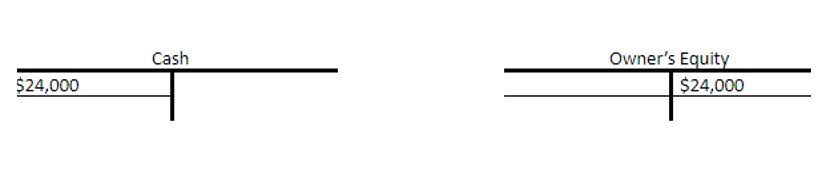

All costs related to the WIP inventory, including the costs of raw materials, overhead costs, and labor costs, need to be considered for the balance sheet to be accurate. Work-in-process inventory refers to all materials to be used in the production of finished goods. Thus, work-in-process stock includes raw materials, overhead costs, and human labor, waiting to be assembled, manufactured, and sold. The cost of goods manufactured (COGM) refers to the total price you have incurred on the production of final products. To calculate the value of your current work-in-process inventory, you must know the final COGM. To determine the value of the cost of manufactured goods, add the total manufacturing costs to your beginning work-in-process stock.

E-commerce Just-in-time inventory

A construction superintendent is the general contractor’s designated representative who oversees part or all of a jobsite for the duration of a project. Prior to joining the construction-software firm, Matt spent five years working as a Project Manager for BIG Construction and Builtech Sevices in Chicago, where he currently resides. Matt received his Bachelor of Arts in Economics from the University of Wisconsin-Madison. Presenting too many options to an owner can lead to delays that are worse than if nothing changed at all. Too many options can be hard to track for the GC, hard to decide between for the owner, and cause the design team to feel that the goal is just to make things cheaply. Even if an owner can make decisions quickly, too many options might push them to unnecessarily try to maximize every little part of the project.

This account of inventory, like the work in progress, may include direct labor, materials, and manufacturing overheads. A company often uses internal allocation methods to determine the work in process example estimated financial value of work in progress. For example, the company must not only assess the financial value of incomplete goods but estimate what percent complete its products are.

What is work in process inventory?

There must be accurate and consistent contact about what’s happening at each stage of the production cycle. Additionally, cloud-based solutions enable multiple stakeholders across different locations to access data simultaneously. This can be critical in ensuring everyone is informed about changes in stock levels or production processes. Having too much WIP inventory can lead to increased costs due to storage fees, higher labor costs, and slower turnaround times for orders. Manual data entry and calculations are time-consuming and leave plenty of room for error. So, investing in construction accounting software such as Deltek + ComputerEase is a good idea to help things run smoothly and avoid errors because it is automatic.

- For starters, accurately calculating your WIP inventory it’ll keep your balance sheet updated with the different types of inventory and not just the goods sold.

- This involves multiplying the number of units in process by the bill of materials for those units.

- For example, you can determine the allocation of overhead costs based on machine hours and labor hours.

- This can be particularly important when you will be working together and cooperating on current and future projects.

- This eats up huge amounts of valuable time and distracts your team from doing higher-level work.